The Best (and Worst) Ways to Glue PVC Pipe — Tested and Rated by FORMUFIT

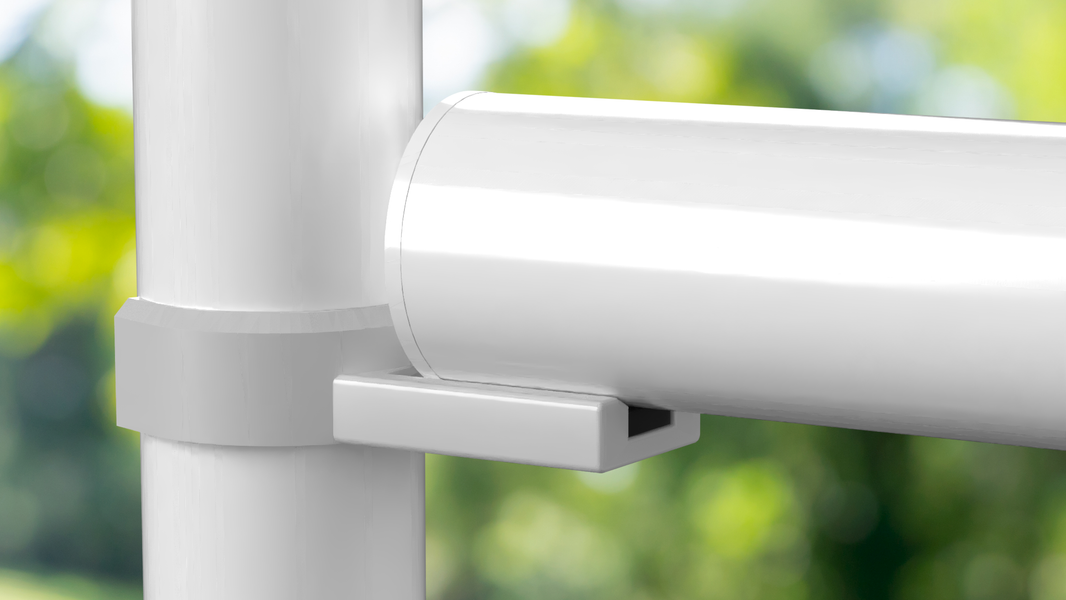

When it comes to building with PVC, the right connection can make or break your project — literally. From furniture builds to DIY rigs, makers have tried every glue under the sun to keep PVC pipe and fittings together. Some work like magic, and others… not so much.

We tested six of the most common PVC bonding methods used by builders, hobbyists, and DIYers, then ranked them from the least effective to the most reliable. Our results might surprise you.

Want to explore other ways to join PVC without glue? Check out our free PVC Assembly Guide to learn about friction-fit, mechanical, and removable methods you can use in your next project.

1. Cyanoacrylate (Super Glue)

Rating: ⭐

Recommendation: Not Recommended

It’s everyone’s first instinct — grab that trusty bottle of Super Glue from the junk drawer and hope for the best. Unfortunately, cyanoacrylate doesn’t play well with PVC’s slick surface. It may bond for a few minutes, but the connection will eventually fail under any real pressure or movement. Skip it for structural builds.

2. Toluene & Xylene (Plastic Cements)

Rating: ⭐⭐

Recommendation: Best to Avoid

These model-building cements are made for polystyrene, ABS, and acrylic — not PVC. They can temporarily soften the surface, but the bond quickly weakens and turns chalky. Great for model cars, not your next PVC project.

3. Rubber Cement

Rating: ⭐⭐⭐

Recommendation: Temporary Hold Only

Rubber cement can fill small gaps between the pipe and fitting, creating a friction-based hold — but it’s not a true adhesive bond. It’s fine for short-term assembly, but the solvents can damage PVC over time. Think of this as a quick fix, not a final build method.

4. Gorilla Glue

Rating: ⭐⭐⭐

Recommendation: Use Only in a Pinch

The Original Gorilla Glue has a reputation for strength, but its polyurethane base needs texture to grab onto — and PVC’s surface is too smooth. It will hold temporarily but will likely separate later. It also expands as it cures, which can distort your fittings. A backup option at best.

5. PVC Cement

Rating: ⭐⭐⭐⭐

Recommendation: Strong and Reliable

This is the classic, tried-and-true method for permanent PVC assembly. PVC cement chemically fuses the pipe and fitting together, creating one continuous piece. Work fast — it sets quickly — and always dry-fit your structure before applying. Perfect for structural builds that never need to come apart.

6. PVC Cement with Clear Primer

Rating: ⭐⭐⭐⭐⭐

Recommendation: The Best Solution

For a flawless, professional connection, pair your PVC cement with a clear primer. The primer cleans and softens the PVC surface, ensuring the cement fuses perfectly. It’s a bit messy — and purple primer will stain — but clear versions are available and worth the effort. The result is a fusion-welded connection that’s strong, permanent, and watertight.

Final Thoughts

From backyard builds to full-sized PVC projects, the right adhesive makes all the difference. For temporary or reusable builds, skip the glue entirely and use mechanical fasteners or PipeClamps. But when permanence matters, use PVC Cement with Clear Primer — the gold standard for strength, durability, and precision.

To explore more ways to build with PVC, visit our PVC Field Guides and learn how to design, connect, and finish your next project like a pro.

8 comments

The primer will dry within seconds. Apply the cement and put together. Your only have a few seconds to put together before it sets up

Hi, when joining a Push fitting pipe together after using the ‘Clear Primer’ and ‘PVC Cement’, how much time is needed before they weld together fully.

Or is it like you mentioned before, where you mark both sections before you push them together.

Could you email me your reply please.

Thanks.

Steve.

Hi, when joining a Push fitting pipe together after using the ‘Clear Primer’ and ‘PVC Cement’, how much time is needed before they weld together fully.

Or is it like you mentioned before, where you mark both sections before you push them together.

Could you email me your reply please.

Thanks.

Steve.