DIY PVC Truck Bed Bike Rack for the Ford Maverick

Matt Hawkins from Cleveland, OH, wanted a simple, affordable, and secure way to haul his fat-tire e-bikes in his Ford Maverick. Most commercial racks either required a trailer hitch or removal of the front wheels — neither of which fit his needs. So, he decided to design his own PVC truck bed bike rack that was lightweight, durable, and easy to remove when not in use.

The Challenge

Matt initially considered a welded metal rack, but quickly realized it would be heavy, require specialized tools, and make his truck bed difficult to use for other hauling needs. After seeing other PVC-based bike racks online, he knew PVC was the right direction — he just needed a design strong enough to support fat-tire e-bikes weighing up to 75 lbs each.

Designing the Rack

After reviewing the FORMUFIT Furniture Grade PVC specifications, Matt chose our materials for their five-times greater strength than plumbing-grade PVC, as well as their UV resistance, impact durability, and color options that eliminated the need for painting.

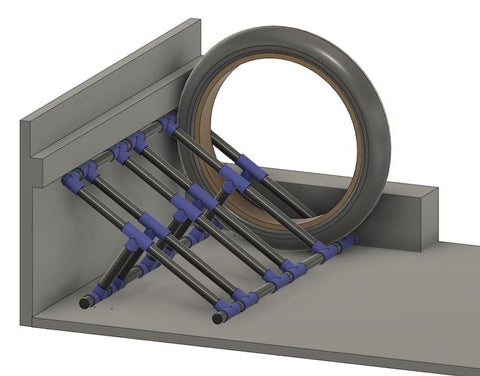

Using Fusion 360 CAD software, Matt imported pipe and fitting data from our technical sheets to digitally model the project. This allowed him to verify exact measurements and confirm that his rack would fit perfectly inside the Maverick’s bed — supporting two e-bikes with 4” x 28.75” tires, or one centered bike if needed.

Material Selection

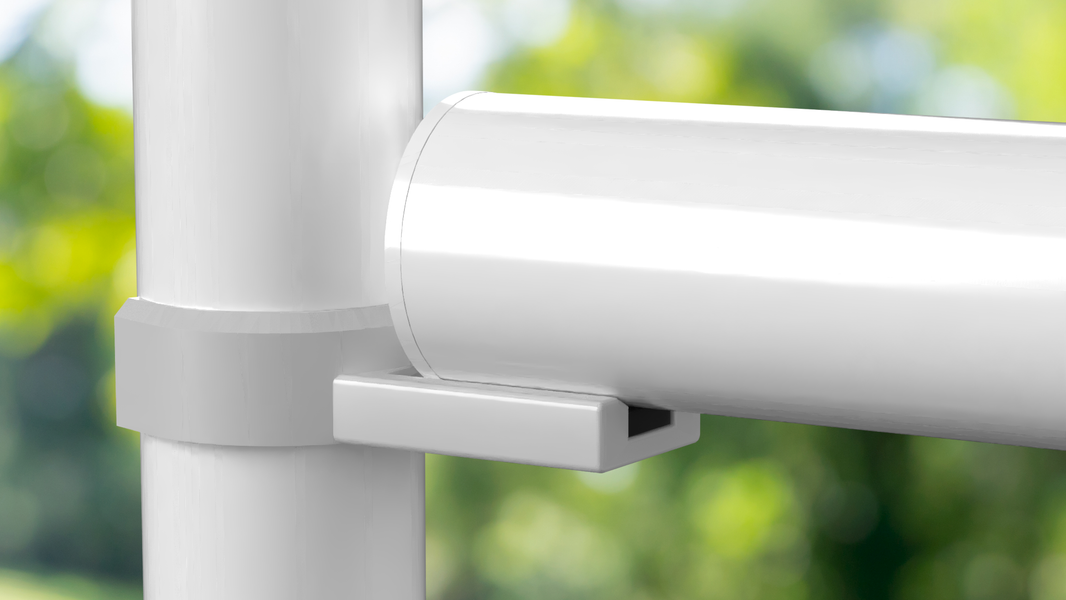

For stability and fit within the truck bed, Matt used 1” Size Furniture Grade PVC for the rack base. He also combined 1” Internal Dome Caps and 1” External Flat End Caps for a secure fit against the truck bed walls.

“The open ends of the PVC pipe that touch the truck bed walls use internal dome caps and external caps. The inner caps fit inside the horizontal ends near the cab, while the flat back section uses external caps for more surface area to hold everything in place.”

Parts List and Cost

“I ordered three two-packs of 1” PVC pipe at 60”, 22 standard tees, two 90° elbows, two internal dome caps, and two external end caps — about $150 total with free shipping. It arrived fast! If you measure carefully, you’ll even have one 60” piece left.”

Assembly and Fit

After cutting the pipe to size, Matt used clear PVC cement and a rubber mallet for precise connections. He assembled the tire slots first, then connected the sections, leaving the bed-contact ends for last to fine-tune spacing. Once completed, he secured the rack using velcro straps attached to the factory tie-downs.

Final Thoughts

“It works great! It doesn’t weigh much and has just enough flex to hold the tires snugly once strapped down. I never thought it would work this well or look this good. Let’s see what you can make with FORMUFIT!”

11 comments

I never glue my projects. I use self taping stainless screws. That way if something should break it is an easy fix.

This is a cool project!!!